When it comes to moving liquid effectively, a diaphragm pump is one of the most reliable tools you can use. Whether you’re in manufacturing, food processing, or even working with chemicals, these pumps play a crucial role in keeping your operations running smoothly. But what exactly is a diaphragm pump, and why should you know about it?

In this article, you’ll learn seven things you need to understand about these pumps. Read on to discover what they are and how they can make your work easier!

1. What Is a Diaphragm Pump and How Does it Work?

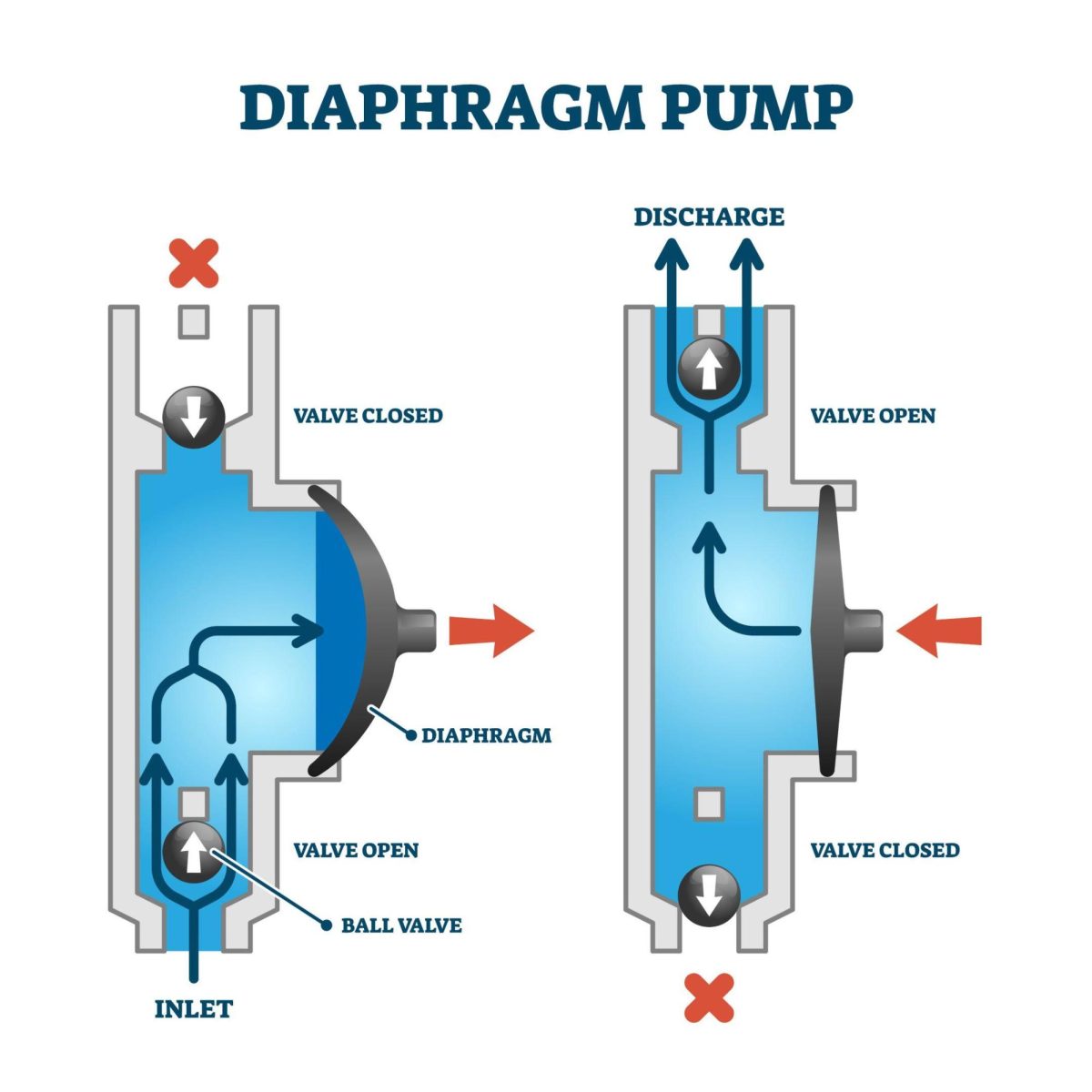

A diaphragm pump moves liquids using a flexible diaphragm. This pump is usually made from materials like rubber or thermoplastic. During diaphragm pump operation, the diaphragm pulls back, creating a vacuum that draws fluid into the pump. When it pushes forward, it forces the fluid out through the outlet.

The pump’s design allows it to handle a wide range of liquids. It works well with both thin fluids and those with higher viscosity. Even liquids with solid particles can move through the pump without causing damage or clogs.

Diaphragm pumps are often used in industries that need reliable fluid transfer. They are common in processes that require moving thicker liquids or chemicals. Their ability to handle tough materials makes them a go-to choice for many businesses.

2. What Makes Diaphragm Pumps Versatile?

Diaphragm pumps are popular because they handle a wide variety of fluids. They can manage abrasive, thick, or even corrosive liquids, which many other pumps struggle with. Since these pumps don’t have seals that can wear out, they are perfect for moving challenging fluids like slurries or chemicals without the risk of leaks.

Another essential feature is that diaphragm pumps are self-priming. This means they can start pumping without needing to fill them with liquid first. These pumps are beneficial when moving fluids from a lower level, like when emptying tanks or containers.

Their durability and flexibility make diaphragm pumps a top choice in industries that deal with harsh fluids. Whether working with heavy-duty materials or delicate chemicals, these pumps can handle it efficiently.

3. What are the Different Types of Diaphragm Pumps?

Diaphragm pumps come in various types, each designed for specific applications and working environments. The two most common types include:

- Double diaphragm pumps: A double diaphragm pump, or Air-Operated Double Diaphragm (AODD) pump, uses compressed air to move two diaphragms in tandem, creating continuous fluid movement. AODD pumps are ideal for hazardous environments as they don’t require electricity and can handle a wide variety of fluids, including slurries and viscous liquids.

- Mechanical diaphragm pumps: Mechanical diaphragm pumps are powered by an electric motor or gearbox. They provide precise control over fluid flow and are more energy-efficient than air-operated counterparts. This makes them ideal for applications like chemical dosing and water treatment.

The bottom line? Both types of diaphragm pumps are highly versatile, self-priming, and durable. However, you’ll need to select which type to use depending on your needs and operating environment.

4. How do You Maintain a Diaphragm Pump?

Maintaining a diaphragm pump is simple but requires regular attention to keep it running smoothly. The diaphragm is the part that experiences the most wear, especially when dealing with abrasive or harsh fluids. Regularly inspecting and replacing the diaphragm ensures the pump stays efficient.

It’s crucial to check the air valve for any debris that may cause clogs. Cleaning out any buildup helps prevent blockages and keeps the pump working properly. Keeping an eye on the valves ensures the pump can handle the fluids without interruptions.

Also, make sure the pump operates within the recommended pressure and temperature limits. Running it outside these limits can cause early wear. Following these simple steps helps maintain the pump’s performance and prevents unnecessary damage.

5. How do You Select the Right Diaphragm Pump?

When choosing a diaphragm pump, there are several factors you should consider to ensure the right fit for your application. To select the diaphragm pump, consider the following:

- Fluid type: Ensure the pump materials are compatible with the fluid you’re moving. For instance, certain chemicals may require a pump made from specific materials to prevent corrosion.

- Flow rate: If you need to move a large volume of fluid, check the pump’s flow rate to see if it meets your needs.

- Pressure: Different diaphragm pumps offer varying pressure capabilities, so be sure to match the pump’s specifications to your application.

Choosing the right diaphragm pump requires careful consideration of the above factors to ensure optimal performance. Matching the pump’s specifications to your specific needs will enhance efficiency and prolong the pump’s lifespan.

6. What are Diaphragm Pumps Used for?

Diaphragm pumps have countless applications across different industries. You’ll often find them in industries like:

- Chemical processing: Diaphragm pumps are excellent for handling aggressive or corrosive chemicals, thanks to their non-metallic components.

- Water treatment: Wastewater management facilities use these pumps to move and process liquids containing solids.

- Food and beverage: These pumps are also great for transporting food products, sauces, or even beverages due to their hygienic properties.

- Pharmaceuticals: In pharmaceutical manufacturing, diaphragm pumps offer sterile and precise liquid transfer.

With their versatility and reliability, diaphragm pumps are essential tools across various industries. They ensure safe and efficient fluid handling without compromising product integrity.

Conclusion

Diaphragm pumps are a versatile and reliable solution for many industries. Their ability to handle a wide range of fluids, from thin liquids to thick slurries, makes them a valuable asset for businesses of all sizes. Whether you’re dealing with thick liquids, corrosive chemicals, or delicate food products, these pumps provide the durability and flexibility needed to get the job done. With the right diaphragm pump, your business will benefit from improved efficiency and reduced downtime.